Choosing the proper lashing system requires to considerate several characteristics which may differ depending on the lashing method used, as explained here.

In this article you will find the presentation of the types of lashing systems and their components, as well as an exhaustive presentation of the different tightening devices available on the market.

What are the components of a lashing system?

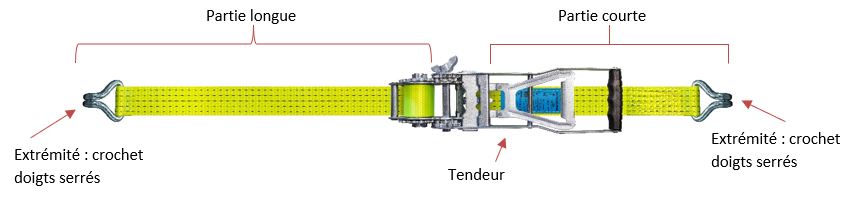

Product info: a lashing system is composed of a sewn webbing, a tightening device (ratchet or buckle) and fittings (hooks). It can be made of 2 or 1 part (belt configuration).

2 parts lashing systems

Two-parts lashing systems are composed of a long part and a short part. The tightening device is usually on the short part. The endingsof the two parts can be identical or different.

1 part lashing system (aka belt configuration)

Belt lashing system is made of a single textile part at the end of which is positioned the tightening device (buckle or ratchet).

Fittings

A 2 parts lashing system has a fitting at each of its ends. Endings can be hooksor clean cuts. They can be identical or different. There are many type of hooks available such as:

Closed wire hook

Hook with latch

Open wire hook

PVC coated hook

Hook for interior lashing

What are the types of tensioning devices available on the market?

Si les éléments à prendre en considération pour les sangles d’arrimage varient en fonction de la méthode d’arrimage (largeur, LC ou encore rupture), les tendeurs quant à eux ne présentent pas tous les mêmes avantages et fonctionnalité. While the considerations for tie-down straps vary depending on the tie-down method (width, LC or even breakage), tensioners do not all have the same advantages and functionalities.

Discover below the main types of ratchets on the market.

Regular ratchet

These are the most common on the market. They are made up of a gear wheeland a handle with a ratchetwhich enables the lashing webbing to be tightened by wrapping it around an axis. You need to lift the handle to induce the rotation of the gearing wheel and the rolling of the webbing to obtain the tension of the system.

Progressive release ratchet

The progressive “notch by notch” release mechanism of the ratchet makes it possible to secure the unloading and to readjust its stability if necessary. This ratchet enables you to gradually, step by step and safely release the force retained in your lashing system. You secure an unbalanced unloading and thus regain control of your cargo. With this system the webbing slowly loosens the load does not fall, the hook does not come offat once.

Good to know

These ratchets are particularly useful for people who are responsible for securing loads alone, their safety is guaranteed thanks to this system whichprevents the load from tipping over.

Ergonomical ratchet

The ergonomic ratchet, also known as inverted ratchet, has reversed gearing system compared to a traditional ratchet. You push down the ratchet’s handle with your body weight to tighten the webbing.

These ratchets are particularly suitable for loads requiring strong tightening, such as logs for example. They make it possible to obtain secure tightening without effort whilepreserving the user’s back, no longer subjected to strong constraints. With this type of ratchet, musculoskeletal disorders are limited.

Good to know

The handle length can be increasedto multiply the effortless tightening force tenfold. With the long handle, the tighteningstrength is enhanced.

Inverted ergonomical ratchet

You push down the ratchet’s handle to tighten the webbing.

Secure and effortless tightening

Ideal for loads requiring strong tightening (such as logs, etc.).

Limitation of musculoskeletal disorders

The operator’s back is preserved

POWERTRUCK

Powertruck is an inverted ergonomical ratchet with a long handle and a gearing system with 3 gear wheels ensuring amultiplied tensioning force.

With a 800 daN STF, it considerably reduces the number of lashing systems required when the friction securing method (aka covering method) is used, and saves precious time on setting up the lashing devices.

Powertruck is intended for use on heavy, large and compacts loads, and for truck drivers who carry out several loading and unloading operations daily.

Multiplied tensioning force

Secure the load, the operator and any third party

Optimization of the lashing process

Tensioning strap buckles

The buckles allow you to close and apply tension to the webbing, replacing a ratchet.

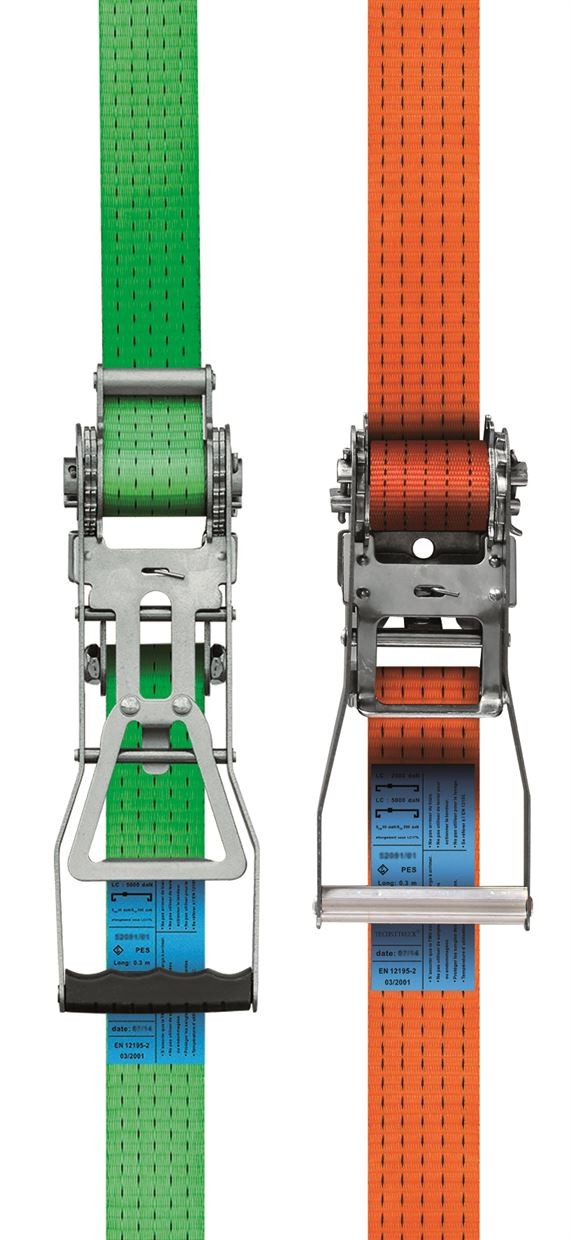

Cam buckles can be used on 1 or 2 parts lashing systems.

1 part

2 parts

As presented in this article, the types of lashing systems can be diverse and varied. As a manufacturer, we are able to offer you tailor-made securing systems, precisely adapted to your needs.

Recent Comments