WEBBING FOR PIPELINE – ENS

To meet with our international customers’ needs, for the past 20 years we have specialized in providing pipelines lifting and handling solutions. Our webbing for pipelines is made of several fixed parts: a wide flat webbing sling with reinforced eyes on a hinge, and a spreader with locking latches.

The range benefits

Safety: wide sling to balance and easily stabilize the pipe. The hoist keeps the webbing perfectly straight all the way across. Balanced dividing up of the sling’s width. A quick and easy setting up. Traceability is guaranteed on each part: traceability label on the webbing, marking plate on the spreader.Our advantages

French manufacturer guarantee

French manufacturer guarantee Customization available

Customization availableAbout this product

Pipes diameters from 6 up to 50 inches and more. 100 % high tenacity polyester fiber webbing and sewing thread. Each element can be replaced alone. Depending on your use, a wide range of protections is available: sprayed polyurethane, polyurethane coating (for webbing between 150 - 450 mm width), or sleeve, etc. Consult us for more information and capacities or for any project study.Features

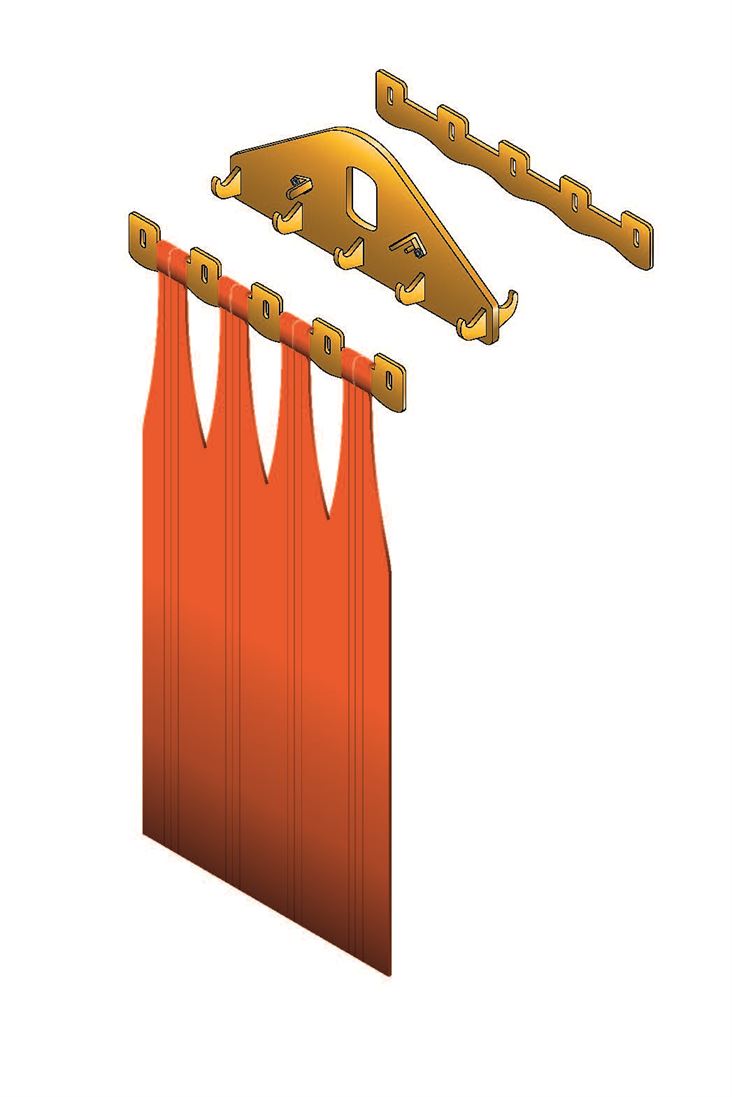

Schéma / Visuels

Configuration: a spreader with many hooks for the webbing fitting and a webbing with steel fitting.

Steel fittings locked with latches.

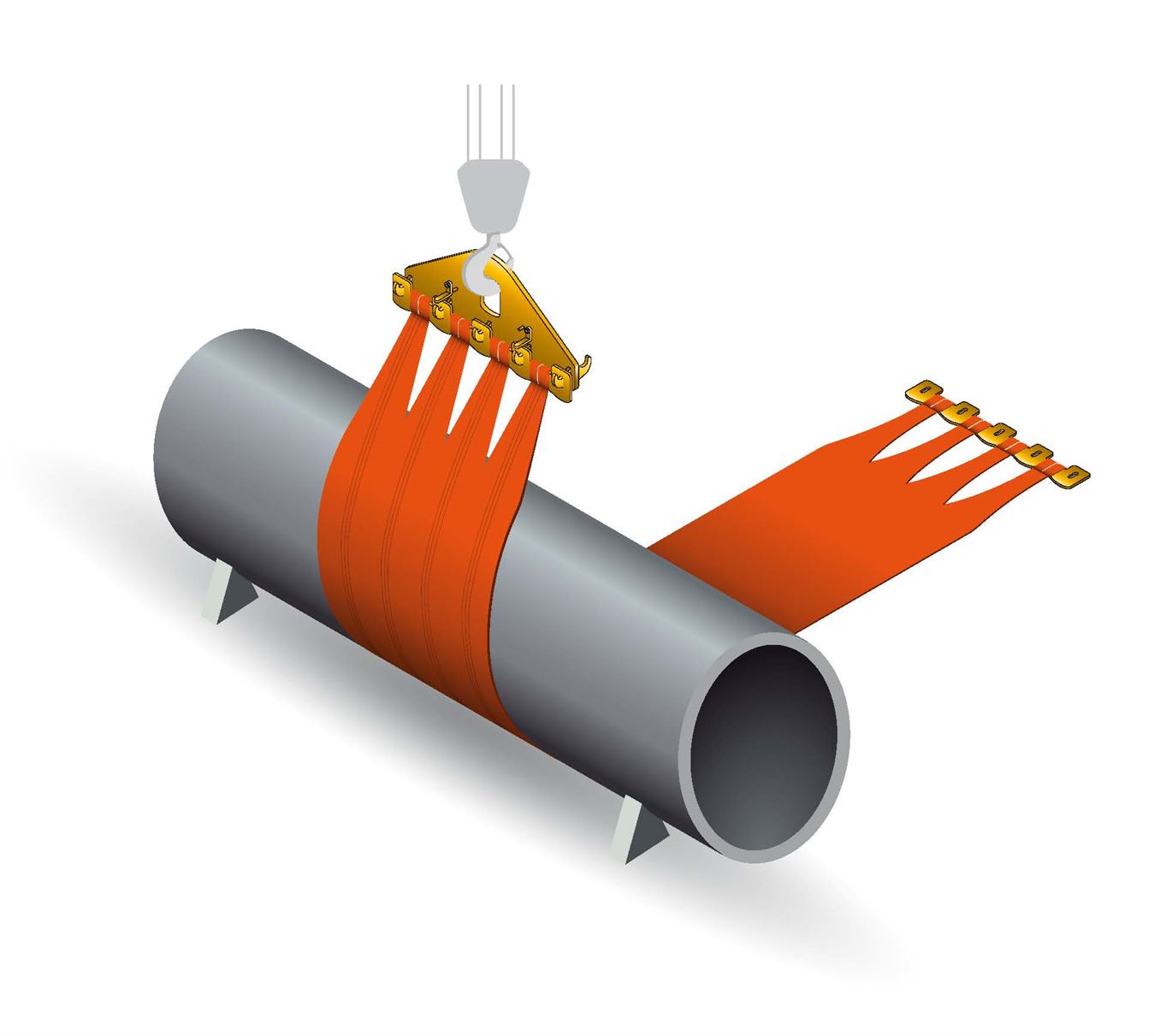

A quick and easy setting up:

1. Hang one of the webbing ending to the spreader.

2. Slide the webbing under the pipe and then hang the second ending of the webbing on the spreader.

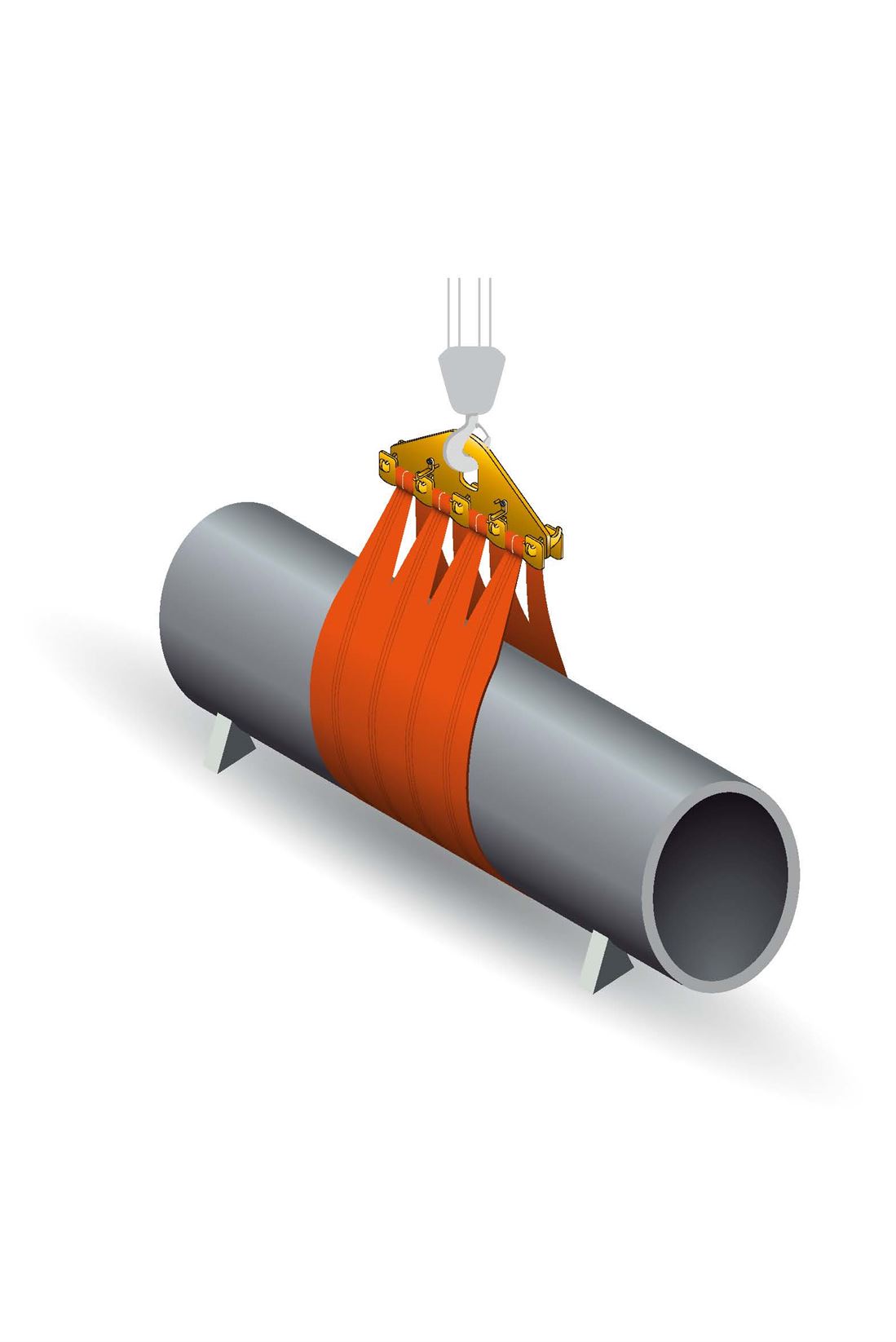

3. Lift the assembly. The webbing’s width ensures the pipe’s stability.

PIPELINE LIFTING AND HANDLING SLING - ENS EVO

PIPELINE LIFTING AND HANDLING SLING - ENS EVO CHOKER BELT- CHO

CHOKER BELT- CHO HOSE SECURING SYSTEM

HOSE SECURING SYSTEM JUXTAPOSED WEBBING SLING - BD

JUXTAPOSED WEBBING SLING - BD HAMMOCK WEBBING SLING - SLDH

HAMMOCK WEBBING SLING - SLDH