Are you looking to understand how to choose your sling? Or simply how to use and maintain it? You are in the right place!

Whether you are new to or experienced in slinging operations, this post will help you learn more about slings, the complexity that lifting operations can represent, and how to properly use your equipment.

What is a sling?

A sling is a removable accessory that enables a machine or device, such as a crane for example, to lift a load by linking the lifting device and the load to be lifted (object, vehicle, etc.).

Slings are essential lifting devices for all lifting operations. This term includes different types of equipment.

The different types of slings

There are several types of single or multi-strand lifting slings, made of textile (polyester, UHMWPE, aramid, etc.), rope, metal cable or even chain. Slings can be equipped with metal components such as hooks, rings or shackles at their ends.

Discover all our slings and lifting accessories .

Choose your sling

Before lifting a load, it is essential to assess and calculate its weight as well as the capacity of the equipment available (crane) in order to choose the sling that will enable you to carry out the lifting operation in complete safety.

The choice of the appropriate sling is made according to:

- The weight, shape and nature of the load and the lifting mode factor to assess the WLL and the type of sling required.

- The environment (temperature, type of exposure, available height, etc.) to assess the type of sling suitable.

- The lifting method, the attachment points and the equipment available.

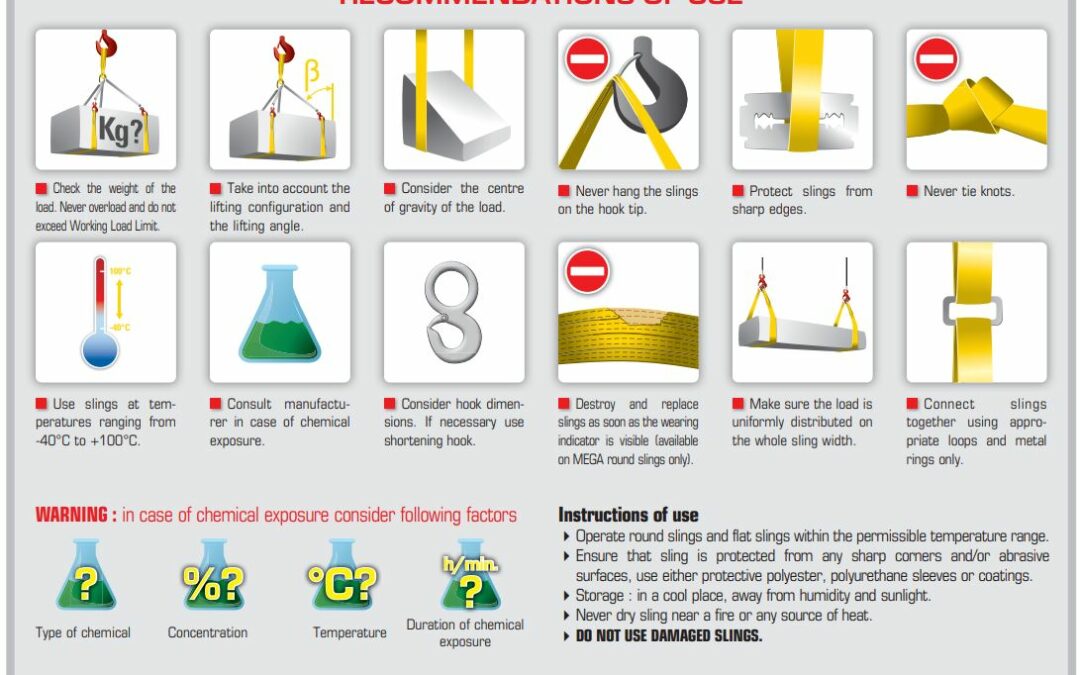

General recommendations

It is recommended to use, store and clean the lifting slings in a specific way in order to preserve them and guarantee safety during use.

The use of lifting slings

Slings must only be used for lifting, in accordance with their instructions for use. The sling selected must be of sufficient strength and length for the load to be lifted. Use the appropriate mode factor, do not overload the slings.

Storage of slings

Store the slings in a cool and clean place, away from humidity, sunlight and chemicals.

Sling cleaning

Never dry sling near a fire or any source of heat. If necessary contact the manufacturer for the appropriate cleaning procedure. Any sling that has been in contact with acids or alkalis needs to be rinsed with water or neutralized with trichloroethylene or tetrachloroethylene.

Obligation of control

Slings must be examined at least once a year by a competent person as part of the mandatory periodic audits. Discover our Scan & Control mechanism, a service for mandatory periodic audits and traceability of our products.

Duty of care

Slings and accessories should be protected from bending forces, sharp edges and risks of friction and abrasion. In the presence of sharp edges and/or abrasive surfaces, it is essential to use PVC or polyurethane protective sheaths or polyurethane-coated slings.

Discover all our polyurethane protections.

Instructions for use of lifting slings

It is important to follow the instructions for use of the slings in order to secure the lifting operation and to maximize the life of the equipment.

How to choose the right sling?

As explained above, choosing your sling starts with calculating the weight of the load to be lifted and determining the appropriate mode factor.

Before use, visually inspect the slings to detect any damage. Any damaged sling should be scrapped.

– Make sure they have no defects,

– Ensure that their identification and specifications are correct via the traceability label or the marking plate.

In the case of combined use of a sling with fittings and/or lifting devices, ensure that these elements correspond to each other.

How to properly carry out its slinging?

Only entrust the slings to competent personnel (trained and experienced).

Slings should be placed over the load so that the load is evenly distributed across their width.

The sling must be fixed in such a way that the load cannot fall during lifting. Position the sling so that the lifting point is directly above the center of gravity and so that the load is balanced and stable.

Avoid damaging labels or marking plates by ensuring that they are not in contact with the load.

In case of lifting with several slings, respect the angles at the top indicated in the tables for multiple slinging.

Only tie webbings or slings together with suitable metal buckles or rings.

When lifting in basket (U) configuration, check that the load is well secured, because with this lifting method it is not immobilized as during tie lifting. When using slings in pairs, it is recommended to use a lifting beam.

Assembly links and other connection systems: check the correct positioning of their constituent elements (half-links, pin, locking system, ring or pin). Check the correct locking of these elements.

Things not to do

It is important to avoid certain actions to preserve the sling and everyone’s safety:

- Avoid any impact or sudden handling of loads

- Avoid shock when tensioning the sling

- Load slowly to check equilibrium conditions

- Never drag a load in the sling and never leave a sling on the ground

- Avoid jamming the sling and do not try to pull it to free it

- Do not leave the load on the sling

- Never stand under the load, never leave a suspended load unattended

- Any technical intervention on the slings, such as heat or surface treatment, grinding, welding, is prohibited.

- Never place the seams of the textile slings on the hooks or other lifting device: always ensure that the seam is located in the vertical or almost vertical part of the sling

- Never twist a sling and never load a sling that has knots

- Never load the hooks on their tips, the load must be centered on the component in such a way as to allow it to “self-center”

- Our multi-leg slings are calculated at 45° in A with respect to the vertical (see sling identification plate). If used at a higher angle, reduce the CMU according to the instructions in the table. Never exceed the WLL of the sling, even if the sling angle is reduced

The resistance of the slings

The heat resistance of slings

Textile slings must be used in compliance with the following temperature conditions:

– 40°C to + 80°C for polypropylene.

– 40°C to + 100°C for polyester and polyamide.

Do not use wire rope slings at a temperature above 100°C or below -40°C for a wire rope with a textile core and between 150°C and -40°C for wire rope with a metal core.

Chain slings must be used between temperatures of + 200°C to – 40°C.

Polypropylene rope slings are suitable for use and storage in temperature ranges from -40°C to 80°C.

These temperatures may vary in a chemical environment. In this case, advice should be sought from the manufacturer or supplier.

Sling resistance to chemicals

The constituent materials of the slings have a selective resistance to chemical attack. Seek advice from the manufacturer or supplier if chemical exposure is likely. The effects of chemicals may increase with temperature.

Slings must not be used in an acidic environment (bath or vapours).

Chemical corrosion causes local weakening and softens the material. This phenomenon is identified by the peeling of the surface fibers which can then be torn or removed by friction.

The resistance of textiles to chemicals is summarized below:

– Polyamides are virtually insensitive to the effects of alkalis. However, they are not resistant to attack by mineral acids;

– Polyester is resistant to mineral acids but not to attacks by alkalis;

– Polypropylene is slightly altered by acids and alkalis; it is suitable for applications requiring high resistance to chemicals (other than certain organic solvents);

– Solutions of harmless acids or alkalis can become sufficiently concentrated by evaporation, which may damage the material. Remove the contaminated webbings at once, immerse them completely in cold water, and let them air dry

Maintenance, repair, reform

In order to maximize their lifespan and safety during use, it is essential to properly maintain your lifting slings.

Repair of slings

Repairs may only be carried out by the manufacturer or a third party appointed by him. Only slings that can be identified by their label can be repaired.

Any damage to the coupling elements or accessories (deformation, crack, etc.) requires the disposal of the slings concerned.

Sling damage

Any damage to the coupling elements or accessories (deformation, crack, etc.) requires the disposal of the slings concerned.

Textile slings: any damage to the sheath indicates a possible deterioration of the core and possible unsuitability of the sling for use.

- A sling with a damaged sleeve to the point of exposing the core should be removed from service for examination by a competent person.

Remark: Studies have shown that polyester undergoes slight degradation over time. Ultraviolet rays of the light alter the breaking strength of the webbing by a few percent. It is therefore advisable to expose as little as possible your slings to the sun’s rays.

Wire rope slings: scrap the sling if it shows signs of breaking (cracks, etc.), excessive corrosion, if the components are damaged, if the cable has stretched or deformed in relation to the dimensions recorded during commissioning.

Chain slings: they must be taken out of service if the links are elongated by more than 5%, crushed, deformed, flattened, elongated, open or show wear reducing the diameter of the curved part by 20% or more; if they show a permanent elongation reaching 5% or if the components are damaged.

As you will have understood, the choice of a lifting sling leaves no room for chance, and is very regulated. The use of lifting slings requires particular vigilance and many precautions in order to guarantee optimal safety over the long term.

It is necessary to ensure a very high quality of manufacture in order to avoid potential problems. The choice of the manufacturer is essential to accompany you, to be able to ensure a serene use and also to help you in the event of damage and the need for repairs. Your safety depends on the proper use of these products, please contact us any questions you may have.