Mandatory periodic audits and traceability by SCAN & CONTROL mechanism

When operating, each lifting or personal protective equipment must be checked at least once a year.

What do you risk not having your equipment checked?

Avoiding the audit of your equipment is risking…

- The accident: using equipment that may be dangerous for the operators.

- Stopping the construction site: and therefore, incurring financial losses.

- A ban on using the material.

- Legal proceedings: due to non-compliance with regulations.

Regulatory reminder

Decree of March 1, 2004, consolidated version of March 26, 2018

French law requires owners of lifting solutions and PPE to carry out periodic general checks on their equipment in order to detect anomalies or any defect that could endanger their life and that of their employees.

Article 24 – Amended by Ordinance n ° 2007-329 of March 12, 2007 – art. 12 (V) Modified by Decree n ° 2008-244 of March 7, 2008 – art. 9 (V):

“The lifting accessories referred to in b of article 2 of this decree, used in an establishment referred to in articles L4111-1 to L4111-3 of the labor code, must, in accordance with articles R4323-23 to R4323-27, R4535 -7 and R4721-11 of said code, be subjected every twelve months to a periodic check comprising an examination intended to verify the good state of conservation of the lifting accessory and in particular to detect any deterioration, such as deformation, hernia , strangulation, broken strand, number of broken wires greater than the admissible one, damaged latch, or other limit of use specified in the manufacturer’s instructions, which could be the cause of dangerous situations. “

Why should you have us checking and maintaining your equipment?

When PMS Industrie carries out your mandatory periodic audits, you are guaranteed quality work, respecting the legislation in force, provided by our years of experience as a manufacturer and specialist in the control of lifting and fall protection equipment.

Together, we plan the equipment control periods so as not to disrupt your business. Our competent technicians carry out periodic checks. They control your equipment in our premises or move around your establishment. You can work in confidence, we bring you security, comfort and serenity.

If necessary, we also offer repair and maintenance, depending on the equipment, and perform recirculation tests on our test benches (Article 8, session 2, decree of March 1, 2004, consolidated version of March 26, 2018).

2 ways are available, depending on your needs:

Inspection of equipment on our premises

This service includes the inspection and the report, at an indicative hourly rate.

On-site equipment inspection

Depending on the location and the quantity of equipment to be checked this service can take a day or half a day. It is carried out by an inspector and includes moving, inspecting and reporting.

What methods do we offer for mandatory periodic audits?

Overview of our methods

There are several methods available for carrying out periodic checks of your equipment:

- The classic method: control and entry of reports in paper version.

- The RFID method: having chips with a radio frequency put in your equipment.

- The computerized method: by scanning bar codes or QR Codes.

To provide you with a service that meets your needs, we now offer solutions adapted to all methods: the traditional way and the computerized solution of Scan & Control. Upon request we are also able to implement your own RFID solutions in our products. This is part of the product customization that we offer as a French Manufacturer.

- 360° support from the study of your needs to after-sales service

- Traceability is guaranteed

- Global, modern, and international solutions

Focus on SCAN & CONTROL, the computerized technique

SCAN & CONTROL is the turnkey solution we offer you.

In line with the partnership philosophy that drives us, we strive to offer you a service and an additional traceability solution for your equipment. By choosing the products and the support of PMS Industrie, you benefit from our know-how as a historical French Manufacturer in the sector.

- We carry out Periodic Mandatory Audits of your equipment for you according to one of the packages presented above (in our premises or on your site).

- You can subscribe to a platform for consulting information relating to the control and monitoring of your equipment.

– Different annual subscription formulas are offered to you depending on your situation, the number of equipment concerned.

– Subscriptions are automatically renewable.

If you have a large amount of equipment concerned, we can put you in touch directly with our service provider to develop a tailor-made solution for you.

The benefits

Scan & Control has several advantages :

- You are automatically informed of your deadlines: renewal of mandatory periodic audits, etc.

- Complete dematerialization of data relating to your equipment: beyond the ecological dimension of this approach, you have the assurance of accessing your documents as soon as necessary without risking losing them.

- Easy storage of all your documents thanks to the dematerialization of your certificates, you have nothing to manage at home, everything is done from the platform.

- You are totally independent thanks to your unlimited and real-time access to the various information and control reports for your products on the mobile application and the internet platform.

- You have easy and independent access to resources to facilitate the management of your equipment (documentary database).

- You benefit from a platform that has already proven itself with teams dedicated to updating it in real time (new features, regulatory monitoring, etc.).

What does the PMS Industrie SCAN & CONTROL subscription consist of?

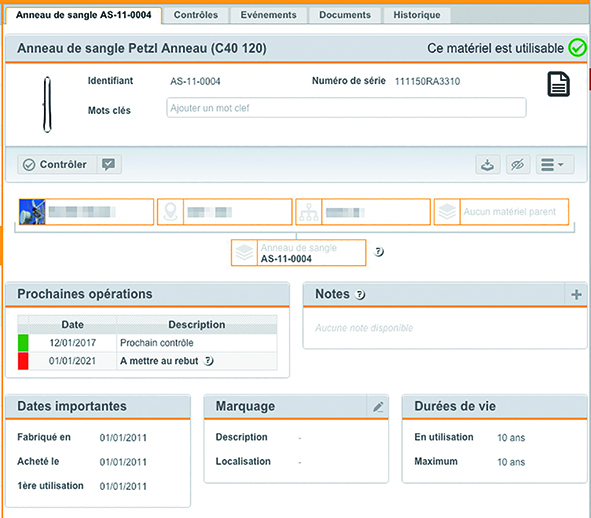

You get personal access to an online platform and a mobile application showing you:

- A list of your equipment concerned by the Mandatory Periodic Audits.

- A dashboard to track your equipment fleet:

– How many products must be checked?

– How many products were found to be compliant?

– How many products need to be repaired or scrapped?

- A regulatory watch to keep you informed of the latest regulations in force in your sector of activity.

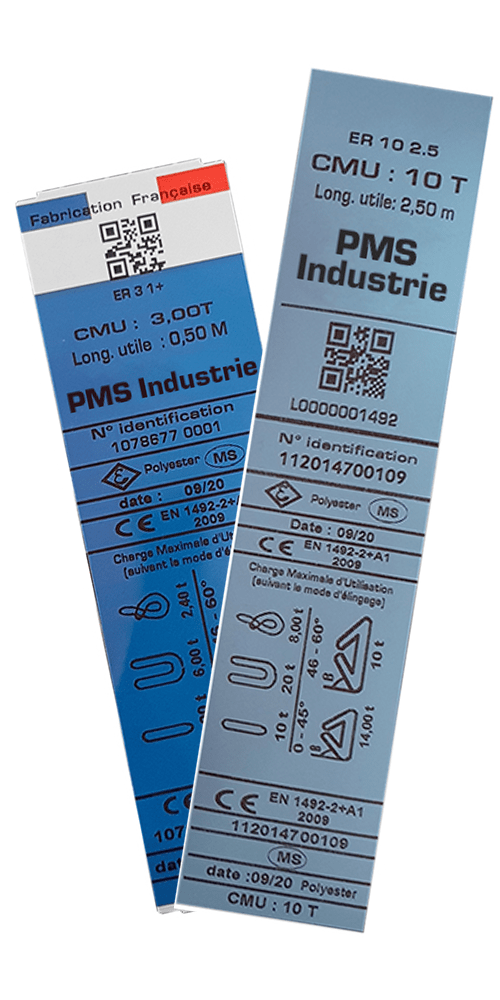

A unique QR code is printed on each traceability label of your equipment. By scanning it via the platform and/or the application you obtain for each product:

- A detailed product sheet: reference, traceability number, inspection history, equipment status, latest comments, upcoming deadlines, etc.

- A documentary base concerning the equipment: technical sheet, inspection report, compliance certificate, user manual, etc.

For more information, request your brochure by contacting us.