POLYSAFE COATINGS – EP1 AND EP2

In accordance with machine directive 2006/42/CE, polyurethane is directly casted for protection purpose on your textile or steel equipment. The POLYSAFE polyurethane coating is applied on a single side or both sides of slings up to 300 mm width and can be processed on any kind of sling – with or without rings – on their whole length if required.

The range benefits

Thanks to its adherence properties, the POLYSAFE coating is recommended for the handling of loads which can slip easily, such as ducts and pipes. It increases the protection of fragile loads (stainless steel ducts and pipes, etc.) and the lifespan of your equipment.Our advantages

A PMS Industrie design

A PMS Industrie design French manufacturer guarantee

French manufacturer guarantee Customization available

Customization availableAbout this product

IMPORTANT: polyurethane coating is applied on the sling surface beside its eyes. For any other type of coating, please consult us. Today, we are one of the leading companies in our market regarding the quality of our products and our reactivity. Our know-how in the field of polyurethane production is recognized worldwide among professionals. Consult us for more information or for any project study.Features

Download center

Schéma / Visuels

Polyurethane is one of the most resistant elements for the protection of webbings or slings when handling sharp or edged objects. It simultaneously protects your load and your lifting equipment.

Polyurethane acts as a shock absorber and extends the lifespan of your equipment: protection against abrasion and cuts.

Document #1

Document #1 POLYSPRAY - PROJECTED POLYURETHANE

POLYSPRAY - PROJECTED POLYURETHANE HONEYCOMB COATING

HONEYCOMB COATING STEEL REINFORCED OVERALL COATING

STEEL REINFORCED OVERALL COATING HANDLING EQUIPMENT PROTECTION - PFPU AND PVPU

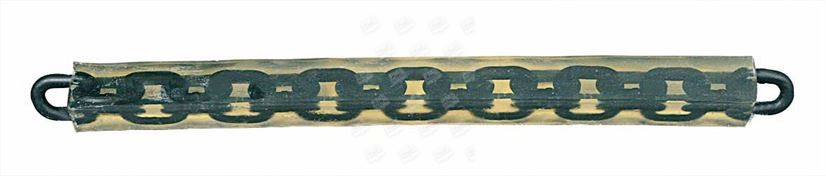

HANDLING EQUIPMENT PROTECTION - PFPU AND PVPU CHAIN OR WIRE ROPE SLEEVES

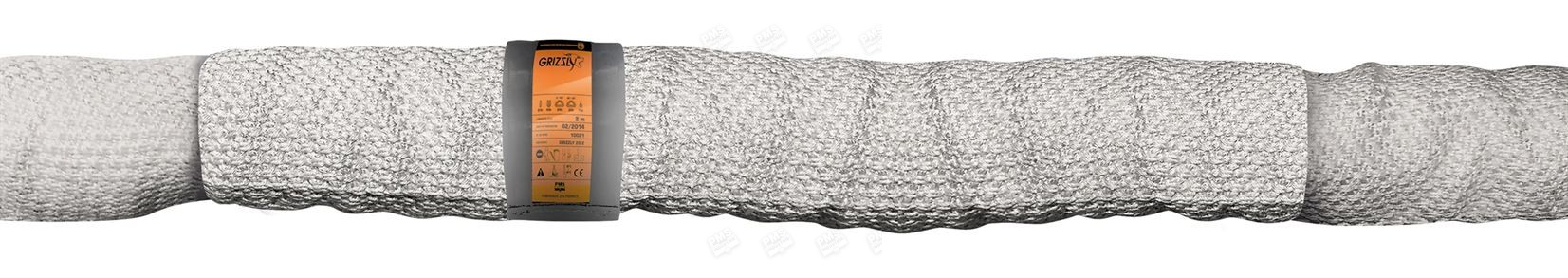

CHAIN OR WIRE ROPE SLEEVES UHMWPE SLEEVES - FGR, PF AND PV GRIZZLY

UHMWPE SLEEVES - FGR, PF AND PV GRIZZLY