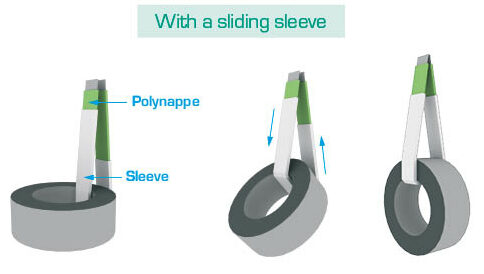

POLYNAPPE WITH POLYURETHANE SLEEVE

The POLYNAPPE with a polyurethane sleeve is specifically designed for the handling of heavy and sharp-edged loads such as coils. It is made of a set of 14 hawsers of steel cable and coated over with polyurethane. Its endings have wire rope loop with polyurethane coating too.

The range benefits

The 2-sided sliding polyurethane sleeve enables the sling to slide and thus ensures perfect tensioning. Virtually no tearing or deterioration. Long lifespan, resists sharpness and abrasion of parts. Shock absorption. Guaranteed traceability.Our advantages

A PMS Industrie design

A PMS Industrie design French manufacturer guarantee

French manufacturer guarantee Customization available

Customization availableAbout this product

Customized lengths possible, contact us.Features

Download center

Schéma / Visuels

As shown on the image, the POLYNAPPE/FP2 sling is adapted for the lifting of coils.

If you were to lift coils without the sliding polyurethane sleeve, the risk for shears and deterioration is higly increased (you can see the potential area for shears on the image).

Document #1

Document #1 POLYNAPPE

POLYNAPPE POLY-CAL

POLY-CAL 100% UHMWPE ROUNDSLINGS FOR HEAVY LIFT - GRIZZLY

100% UHMWPE ROUNDSLINGS FOR HEAVY LIFT - GRIZZLY BRAIDED SLING WITH SIMPLE EYES - ECA015A

BRAIDED SLING WITH SIMPLE EYES - ECA015A BRAIDED SLING WITH SIMPLE BRAIDED EYES - ECA014A

BRAIDED SLING WITH SIMPLE BRAIDED EYES - ECA014A